Perfume Bottle Decoration

Customized what you need

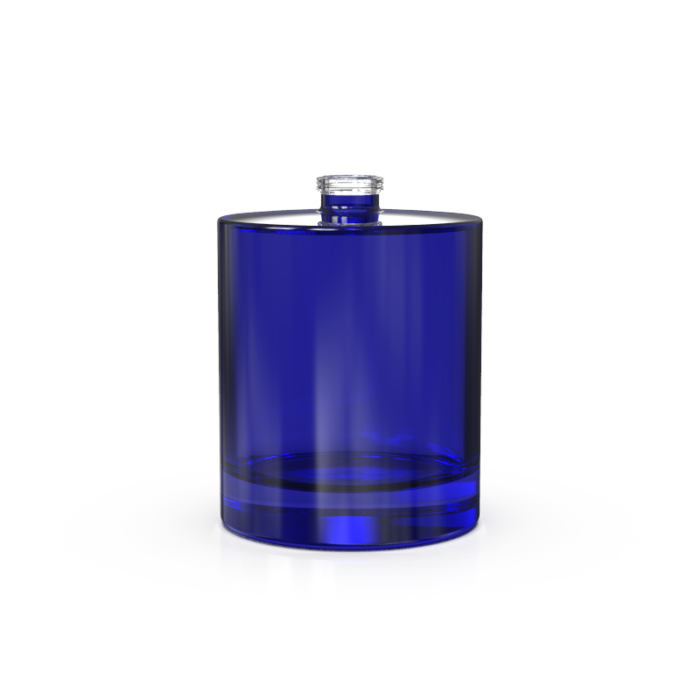

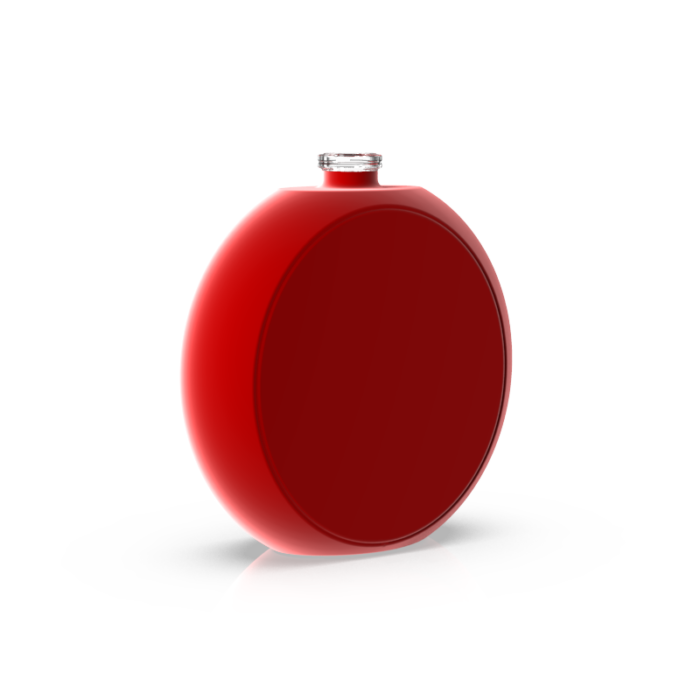

Color Coating

It is one of the most commonly used processes. It can be easily divided into transparent spray and solid paint. The spray can be monochrome, multi-color or gradient, and can be sprayed locally.

Hot stamping

Hot stamping will have a gorgeous luster.It has a unique metallic appearance and is unique which makes the product shine and has more color choices.It can provide you with a shiny relief look

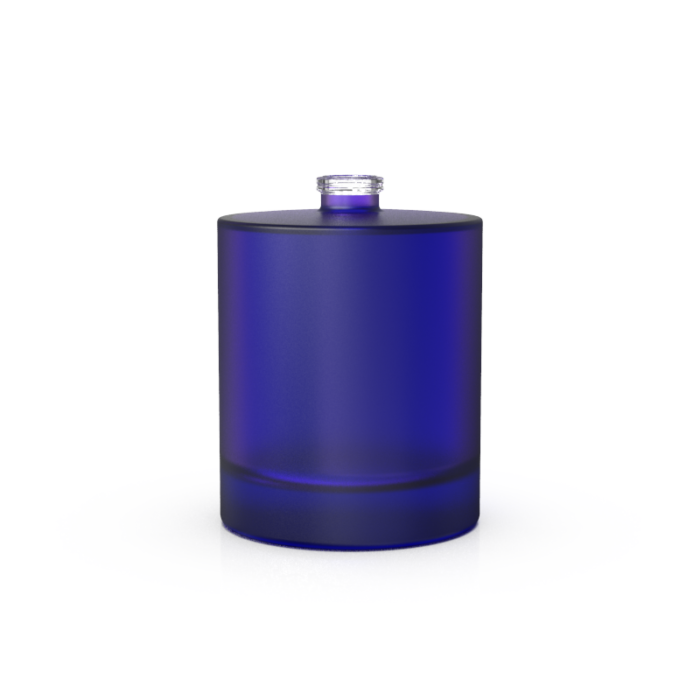

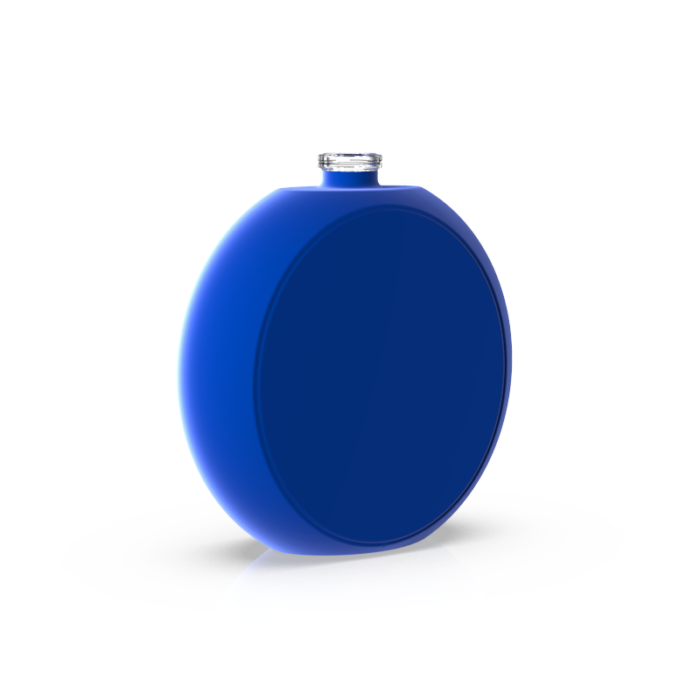

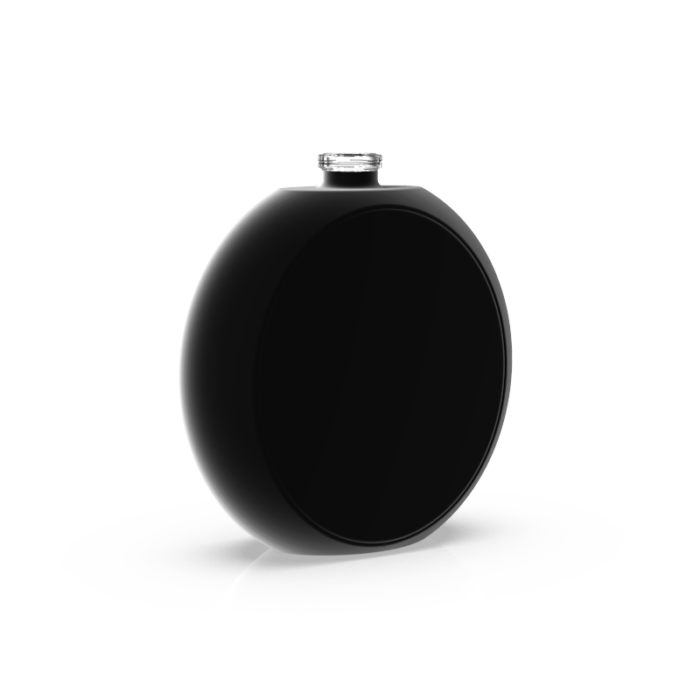

Rubber Coating

Rubber paint is applied to the surface of various materials, and there are many colors to choose from, because it has a soft touch, which makes the product very unique and has a unique charm, making the product more noble and elegant.

Metalizing

Metallization creates a high-end bottle with a personalized look, and the striking decorative effect highlights the uniqueness of the product. The product is metallic and looks more high-end, and its appearance and wear resistance are better.

Polishing

Polishing refers to the use of chemical or physical methods to remove the lines, scratches and scratches on the surface of the glass inorder to increase the transparency and refractive index of the glass and make the glass more vitrified.

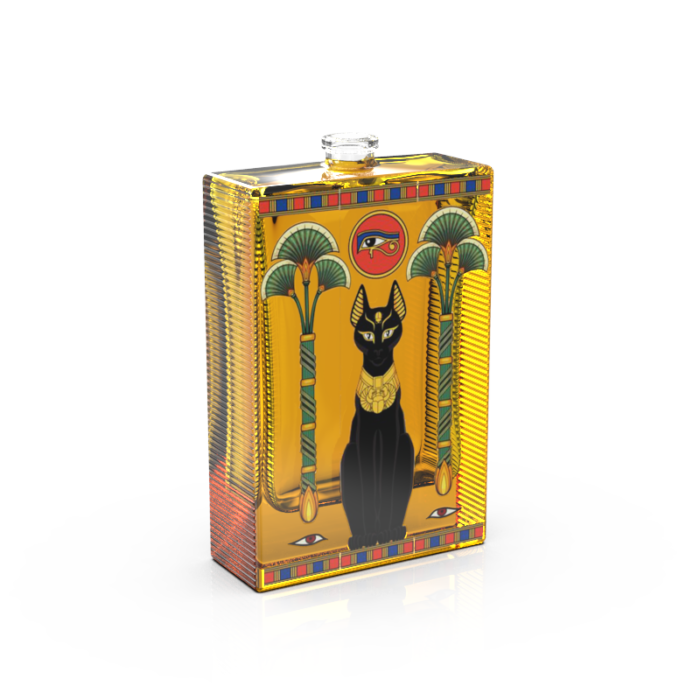

Water Transfer

Water transfer is a surface decorating process where intricate graphics like wood grain,carbon fiber,camouflage,or designer patterns are applied to 3-dimensional plastic produces. This allows more content,images and graphics to be placed onto the product as well as very intricate designs that just cannot be achieved through normal printing. Water transfers is one of the highest quality decoration,any design can be created no matter how big or small and applied to the glass.

Decal

When the shape of the bottle is too irregular to the automatic screen printing process, the decal can be applied manually. The term "sticker" refers to the substrate or the design contained therein, the decal pattern is rich, and the applique is strong. A substrate having a design, pattern or image thereon that is intended to be transferred to another surface.

Cracking

Cracking decorative effect is accomplished by using a cracking medium between a base coat of one color and a top coat of a different color. The cracking medium causes the top coat of paint to crack in random patterns, allowing the base coat color to show through. Cracking is a unique spary tha allows the secondary spray to expand during curing.

Inside coating

INSIDE COATING is a decorative coating applied to the inner surface of the glass bottle. INSIDE resists prolonged contact with alcoholic fragrances. INSIDE highlights the optical effects created by the various thicknesses of the glass, generating true 3D effects. INSIDE is compatible with all traditional decoration techniques such as screen printing, hot marking or lacquering, allowing the interior and exterior of the product to be personalized. INSIDE can give life to your creative ideas.

Flocking

FLOCKING is a technique that allows the application of synthetic fibers on the surface of an object previously covered with glue, creating a velvet effect that is uniform and pleasant to the touch. The colors are varied and this process is compatible with other organic decoration techniques.

For the first time in the field of luxury perfumery and on an industrial scale, G&S has developed a specific glue and an application process on the glass that allows the coating to withstand all the tightness tests in the sector.

Sandblasting

It uses the machine to punch out the desired pattern on the surface of the glass bottle by pressure, and has a more obvious concave and convex feeling. The structure of the blasting surface is determined by the air flow velocity and the hardness of the gravel.

Frosting

Frosting decoration, is a technique used to create a frosted or matte appearance on the surface of glass objects. This method leverages machinery to achieve the desired pattern through controlled abrasion and pressure, resulting in a distinctive sensation.